BeBop's Strip Tease Part I

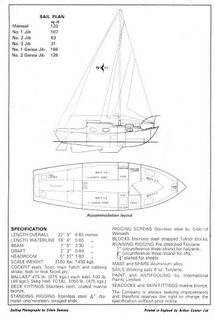

Man am I tired after a full weekend of working on BeBop. My hands have a bluish stain to them, my fingerprints are sanded off and they are mostly numb from running the orbital sander for about 12 hours but I'm 90% done with the above waterline areas that need to be painted now. For my 2.5 viewers you know from previous posts what BeBop looked like with the blue hull. I really didn't like that so it had to go. Besides in the tropics that would make the interior like an oven. Investigating the cost of marine strippers I didn't like what I found. They were trying to sell the stuff for about $50 bucks a gallon because it had the name "marine" on the bucket. Ouch. So off to Home Depot I went to see if I could find anything cheaper. I discovered a product called Citristrip. Safe for plastic and no harsh fumes, I picked up 2 gallons for $18 bucks a pop and came out like $60 bucks ahead. I also picked up some cheap plastic sheeting to cover the areas to be stripped so it gets maximum staying power. Here is a picture of what BeBop looked like with the 1st coat of stripper applied and the plastic sheeting on.

Now I thought this was going to be cake. Hahahaha!!! Absolutely wrong! BeBop is a 37 year old boat and I don't think she was ever stripped down to the gelcoat before. It took me 3 coats of Citristrip applied every 30 minutes to get something close to what you see below. I tried keeping it on longer but it didn't seem to make a difference on how well the stuff worked. To make it more interesting it appears that somebody in the past painted above the waterline to the rub rail with anti-fouling paint. Anti-fouling paint totally laughs at stripper and the stuff is sandpaper's worst nightmare so we could only get it to this point before having to used the orbital.

Sweat equity time. I quickly learned that you have to wait for the sides to completely dry or you'd just load up the sandpaper with paint in about 10 seconds. During the time I was initially stripping and waiting for the washed off areas to dry I did some work on the yacht tender to fill the time, but I'm saving that story for a slow weekend so no details for now. After the sides dried out enough to sand, I used the Dewalt orbital with 220 grit on it to take off the final paint covering the gelcoat and I used roughly 50 sanding pads. I'd like to interject here that I'm very surprised my sander hasn't died yet. I've used it to rebuild my old cafe racer motorcycle, 1 homemade sailboat Rich is making, 1 yacht tender, many numerous other smaller jobs and now about 400 square feet of gelcoat covered with some nasty stripper resistant paint. If your going to buy a orbital sander do yourself a favor and get a Dewalt. They should pay me for the free advertising but I stand by a excellent product and smash a bad one.

Here is my last picture with how BeBop looks now with all the blue paint off the sides down to the waterline. Wow, that was hard but she's beginning to look closer to what I had in mind. I'd like to put in a hearty thank you to Rich for helping me put on the stripper and plastic and working on the dock bumpers too. I figure when he gets his boat I'll be spending my time helping him on his refit as payment.

Sanding all this down generated a crazy amount of dust. I think I'll spend the next weekend sanding the waterline down to the keels so that when I paint and prime the topsides I won't get dust all over freshly painted areas. The bottom won't be going down to the gelcoat because it's not necessary imho. There are no blisters and the paint was designed to live in a saltwater environment so I'll just sand it clean for the next coat. Now dear reader I must get some sleep. I have body parts on my body parts that hurt after this weekends work.

Next week on BeBop Around the World: BeBop's Strip Tease Part II